- Locomotive

-

Freight Car

- Freight Services

- Digital Intelligence

-

Transit

RAIL COMPONENTS

Overview Braking Systems Couplers & Draft Gears Door & Access Solutions Electrical Solutions HVAC & Comfort Systems Power Collection Power & Auxiliary Energy Solutions Sanitation Systems Suspension & Vibration ControlBUS COMPONENTS

Overview Bus Components Doors & Accessibility E-Bus Charging Electric Power Collection Passenger Information & Vehicle SecurityDIGITAL INTELLIGENCE

Radar AIC Event Recorders iSmart Display Passenger Information & Video SecuritySERVICES

Transit Services - Mining

-

Adjacent Solutions

Adjacent Solutions

RAIL INFRASTRUCTURE

Overview Track Products & Materials Signal Wayside Components Vehicle Equipment Electric Power SupplyHEAT TRANSFER & ENERGY SOLUTIONS

Overview Diesel & Gas Engine Cooling Generator, Motor & Transformer Coolers High Temperature Applications -

This website no longer supports the Internet Explorer web browser.

Microsoft is retiring and will no longer support Internet Explorer. Please use another web browser to access this website.

Main Menu

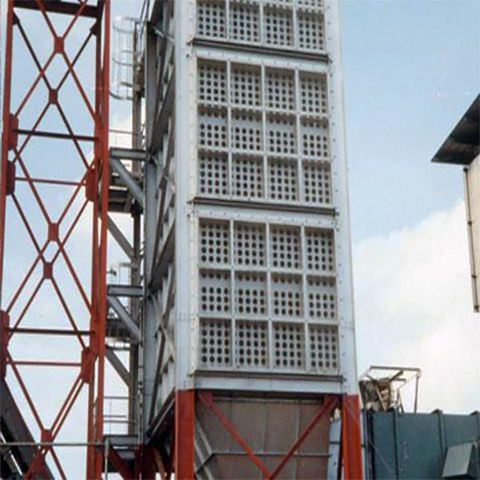

Convection Recuperators

Tubular heat exchangers that utilize convection heat transfer to preheat combustion air or gas for saving fuel.

Convection recuperators are comprised of tube bundles with the tubes welded to the tube sheets to assure gas tightness. Tube arrangement, tube material and flow pattern are based on the specifics of each individual application, including temperatures, compositions, pressure drop limits and space availability.

In a typical design, the hot waste gas from the furnace flows horizontally through the recuperator, passing outside of vertical tubes. Combustion air en route to the burners makes two or more passes inside the tubes in a counter cross-flow pattern.

Applications:

- Steel soaking pits

- Steel reheat furnaces

- Steel heat treat furnaces

- Steel anneal and pickle lines

- Steel galvanizing lines

- Direct reduced iron furnaces

- Aluminum melting furnaces

- Aluminum de-lacquering systems

- Aluminum heat treat furnaces

- Ceramic and refractory kilns

- Thermal oxidizers

- Waste incinerators

Key Benefits:

By recovering heat from the hot waste gas exiting a furnace and transferring it to the combustion air feeding the burners, fuel usage can be reduced by an average of twenty-five percent (25%), and in many cases, greater savings are realized. Waste gas temperatures entering convection recuperators are usually in the 1500°F to 2000°F range, and combustion air preheat temperatures are usually in the 800°F to 1200°F range.

For high temperature industrial furnaces, such as steel reheat furnaces, recuperators are valuable tools for increasing furnace efficiency. Up to sixty percent (60%) of the available energy in the fuel may be carried out of the furnace in the waste gas, therefore, heat recovery is essential for fuel conservation and economical operation. With fuel costs rising, recuperation is certain to play a vital role in the future.